6 x 37 Classification Wire rope

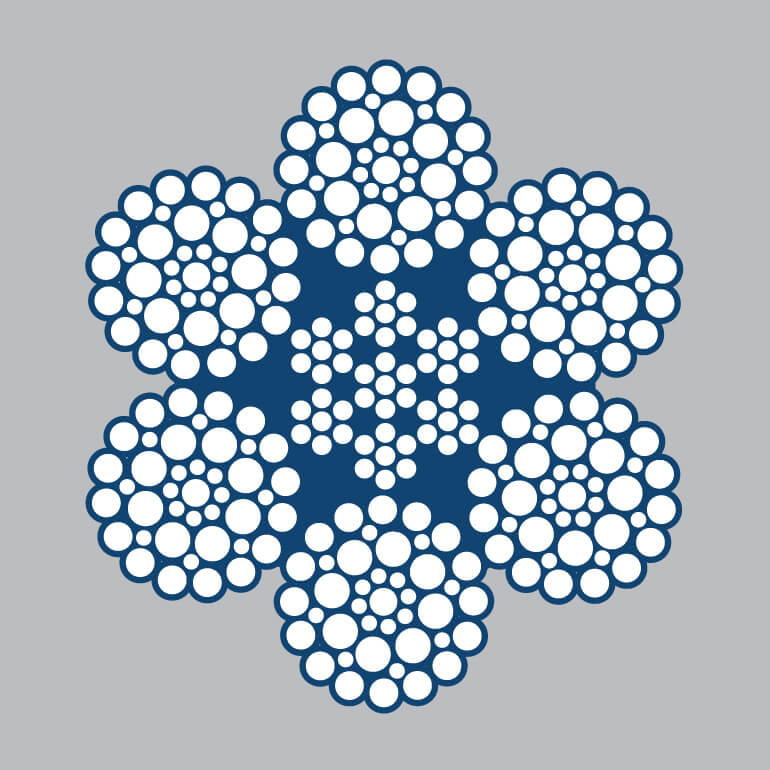

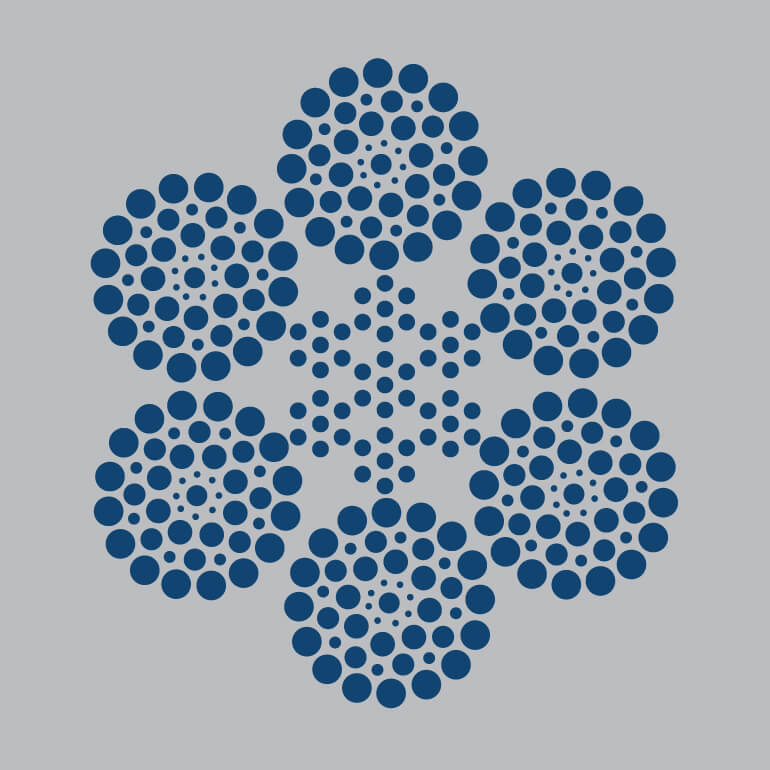

6×37 Classification

More flexible but less abrasion resistant than the 6 x 19 classification. Each strand contains numerous small diameter wires. As the number of wires increases, flexibility increases. 6 x 37 classification ropes contain 6 strands with 27 through 49 wires, no more than 18 of which are outside wires.

IWRC shown; Fiber Core available

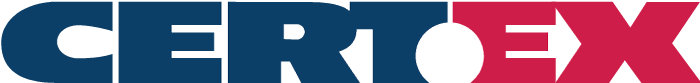

6 x 31 Warrington Seale

Characteristics

12 outside wires. Slightly more flexible than 6 x 25 rope with the same abrasion resistance

Typical Applications

- Overhead Crane

- Mobile Crane Hoist Ropes

IWRC shown; Fiber Core available

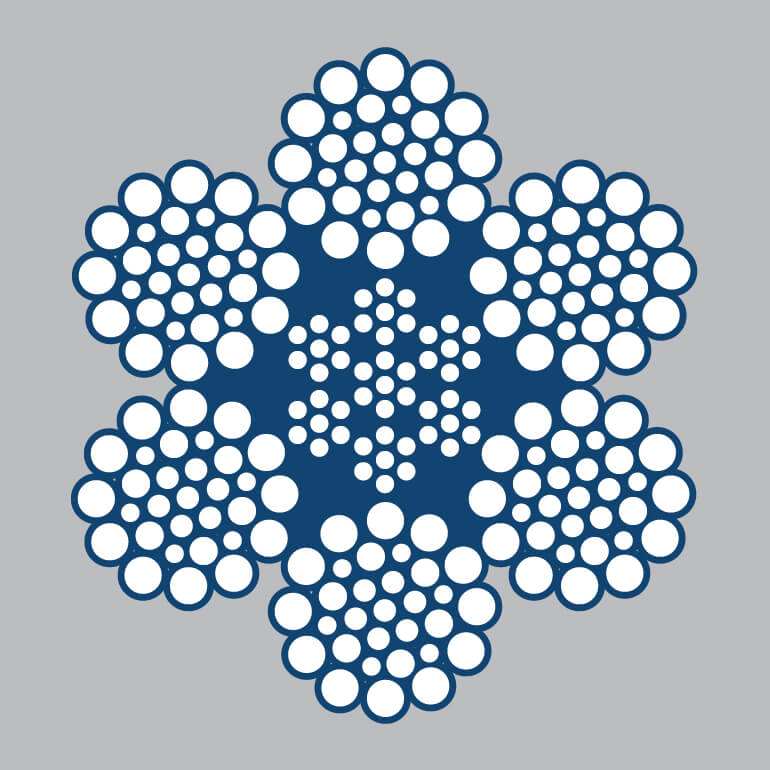

6 x 36 Warrington Seale

Characteristics

14 outside wires. More fatigue resistance; but less abrasion resistance than 6 x 25 rope.

Typical Applications

- Overhead Crane Ropes

- Mobile Crane Hoist Ropes

- Winch Lines

- Large Diameter Towing Lines

IWRC shown; Fiber Core available

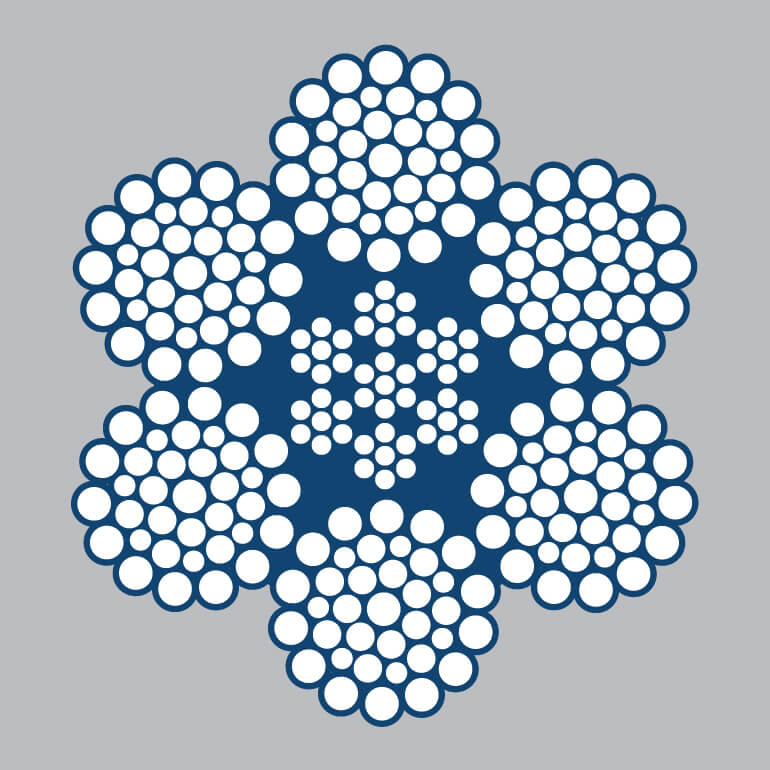

6 x 41 Warrington Seale

Characteristics

16 outside wires. Good combination of fatigue and abrasion resistance for operating ropes.

Typical Applications

- Overhead crane Ropes

- Mobile Crane Hoist Ropes

- Shovel and Dragline Hoist Ropes

IWRC shown; Fiber Core available

6 x 41 Seale Filler Wire

Characteristics

16 outside wires. Good combination of fatigue and abrasion resistance for operating ropes.

Typical Applications

- Overhead crane Ropes

- Mobile Crane Hoist Ropes

- Shovel and Dragline Hoist Ropes

IWRC shown; Fiber Core available

6 x 49 Seale Warrington Seale

Characteristics

16 outside wires. Best fatigue resistance and abrasion resistance in 6 x 37 classification

Typical Applications

- Mooring Lines

- Towing Lines

- Anchor Lines

- Shovel and Dragline Hoist Ropes

| 6 x 37 Classification Rope | ||||||||||

| Diameter, in. | Nominal Strength, Tons (Bright or Drawn Galvanized)† | Approximate Wt./Ft., lb. | ||||||||

| EEIP | EIP | IWRC | Fiber Core | |||||||

| CERTEX Cat. Ref. No. |

IWRC | CERTEX Cat. Ref. No. |

Fiber Core | CERTEX Cat. Ref. No. |

IWRC | CERTEX Cat. Ref. No. |

Fiber Core | |||

| 1/4 | — | — | CX01-0113 | 3.40 | CX01-0155 | 3.02 | 0.116 | 0.105 | ||

| 5/16 | — | — | CX01-0114 | 5.27 | CX01-0156 | 4.69 | 0.180 | 0.164 | ||

| 3/8 | — | — | CX01-0115 | 7.55 | CX01-0157 | 6.71 | 0.260 | 0.236 | ||

| 7/16 | — | — | CX01-0116 | 10.2 | CX01-0158 | 9.09 | 0.35 | 0.32 | ||

| 1/2 | CX01-0077 | 14.6 | CX01-0095 | 12.9 | CX01-0117 | 13.3 | CX01-0159 | 11.8 | 0.46 | 0.42 |

| 9/16 | CX01-0078 | 18.5 | CX01-0096 | 16.2 | CX01-0118 | 16.8 | CX01-0160 | 14.9 | 0.59 | 0.53 |

| 5/8 | CX01-0079 | 22.7 | CX01-0097 | 20.0 | CX01-0119 | 20.6 | CX01-0656 | 18.3 | 0.72 | 0.66 |

| 3/4 | CX01-0080 | 32.4 | CX01-0098 | 28.6 | CX01-0120 | 29.4 | CX01-0657 | 26.2 | 1.04 | 0.95 |

| 7/8 | CX01-0081 | 43.8 | CX01-0099 | 39.0 | CX01-0121 | 39.8 | CX01-0658 | 35.4 | 1.42 | 1.29 |

| 1 | CX01-0082 | 56.9 | CX01-0100 | 50.6 | CX01-0122 | 51.7 | CX01-0659 | 46.0 | 1.85 | 1.68 |

| 1 1/8 | CX01-0083 | 71.5 | CX01-0101 | 63.6 | CX01-0123 | 65.0 | CX01-0660 | 57.9 | 2.34 | 2.13 |

| 1 1/4 | CX01-0084 | 87.9 | CX01-0102 | 78.2 | CX01-0124 | 79.9 | CX01-0661 | 71.0 | 2.89 | 2.63 |

| 1 3/8 | CX01-0085 | 106.0 | CX01-0103 | 94.0 | CX01-0125 | 96.0 | CX01-0662 | 85.4 | 3.50 | 3.18 |

| 1 1/2 | CX01-0086 | 125.0 | CX01-0104 | 111.0 | CX01-0126 | 114.0 | CX01-0663 | 101.0 | 4.16 | 3.78 |

| 1 5/8 | CX01-0087 | 146.0 | CX01-0105 | 129.0 | CX01-0127 | 132.0 | CX01-0664 | 118.0 | 4.88 | 4.44 |

| 1 3/4 | CX01-0088 | 169.0 | CX01-0106 | 190.0 | CX01-0128 | 153.0 | CX01-0665 | 136.0 | 5.67 | 5.15 |

| 1 7/8 | CX01-0089 | 192.0 | CX01-0107 | 171.0 | CX01-0129 | 174.0 | CX01-0666 | 155.0 | 6.50 | 5.91 |

| 2 | CX01-0090 | 217.0 | CX01-0108 | 194.0 | CX01-0130 | 198.0 | CX01-0667 | 176.0 | 7.39 | 6.72 |

| 2 1/8 | CX01-0091 | 243.0 | CX01-0109 | 215.0 | CX01-0131 | 221.0 | CX01-0668 | 197.0 | 8.35 | 7.59 |

| 2 1/4 | CX01-0092 | 272.0 | CX01-0110 | 240.0 | CX01-0132 | 247.0 | CX01-0669 | 220.0 | 9.36 | 8.51 |

| 2 3/8 | CX01-0093 | 301.0 | CX01-0111 | 266.0 | CX01-0133 | 274.0 | CX01-0670 | 244.0 | 10.4 | 9.48 |

| 2 1/2 | CX01-0094 | 332.0 | CX01-0112 | 293.0 | CX01-0134 | 302.0 | CX01-0671 | 269.0 | 11.6 | 10.5 |

| 2 5/8 | — | — | CX01-0135 | 331.0 | — | 12.8 | 11.6 | |||

| 2 3/4 | — | — | CX01-0136 | 361.0 | — | 14.0 | 12.7 | |||

| 2 7/8 | — | — | CX01-0137 | 392.0 | — | 15.3 | 13.9 | |||

| 3 | — | — | CX01-0138 | 425.0 | — | 16.6 | 15.1 | |||

| 3 1/8 | — | — | CX01-0139 | 458.0 | — | 18.0 | 16.4 | |||

| 3 1/4 | — | — | CX01-0140 | 492.0 | — | 19.5 | 17.7 | |||

| 3 3/8 | — | — | CX01-0141 | 529.0 | — | 21.0 | 19.1 | |||

| 3 1/2 | — | — | CX01-0142 | 564.0 | — | 22.7 | 20.6 | |||

| 3 5/8 | — | — | CX01-0143 | 602.0 | — | 24.3 | — | |||

| 3 3/4 | — | — | CX01-0144 | 641.0 | — | 26.0 | — | |||

| 3 7/8 | — | — | CX01-0145 | 680.0 | — | 27.7 | — | |||

| 4 | — | — | CX01-0146 | 720.0 | — | 29.6 | — | |||

| 4 1/8 | — | — | CX01-0147 | 761.0 | — | 31.4 | — | |||

| 4 1/4 | — | — | CX01-0148 | 803.0 | — | 33.4 | — | |||

| 4 3/8 | — | — | CX01-0149 | 846.0 | — | 35.4 | — | |||

| 4 1/2 | — | — | CX01-0150 | 889.0 | — | 37.4 | — | |||

| 4 5/8 | — | — | CX01-0151 | 934.0 | — | 39.5 | — | |||

| 4 3/4 | — | — | CX01-0152 | 979.0 | — | 41.7 | — | |||

| 4 7/8 | — | — | CX01-0153 | 1024.0 | — | 43.9 | — | |||

| 5 | — | — | CX01-0154 | 1070.0 | — | 46.2 | — | |||

*Acceptance strength is not less than 2 1/2% below the nominal strengths listed. †Galvanizing: For class A galvanized wire rope (EIP and IPS grades only), deduct 10% from the nominal strength shown.

WARNING: Any warranties, expressed or implied, concerning the use of this product apply only to the nominal strength of new, unused wire rope. All equipment using this product must be properly used and maintained. Wire rope must be properly stored, handled, used and maintained. Most importantly, wire rope must be regularly inspected during use. Damage, abuse or improper maintenance can cause rope failure. Consult the AISI Wire Rope Users Manual, ASME or ANSI Standards, before usage. Wire rope removal criteria are based on the use of steel sheaves. If synthetic sheaves are used, consult the sheave equipment manufacturer. WARNING!